- Product overview

- All features

- Latest feature release

- App integrations

- project icon Project management

- goal icon Goals and reporting

- asana-intelligence icon Asana AI

- workflow icon Workflows and automation

- portfolio icon Resource management

- my-task icon Admin and security

- list icon Personal

- premium icon Starter

- briefcase icon Advanced

- Goal management

- Organizational planning

- Project intake

- Resource planning

- Product launches

- View all use cases arrow-right icon

- Help Center

- Asana Academy

- Certifications

- Work management hub

- Customer stories

- Get support

- Developer support

- Customer Success

- Project plans

- Team goals & objectives

- Team continuity

- Meeting agenda

- View all templates arrow-right icon

- Project management |

- What is 8D? A template for efficient pr ...

What is 8D? A template for efficient problem-solving

How you respond when problems arise is one of the most defining qualities of a manager. Luckily, there are tools you can use to master problem-solving. The 8D method of problem-solving combines teamwork and basic statistics to help you reach a logical solution and prevent new issues from arising.

You’ve spent months overseeing the development of your company's newest project. From initiation, planning, and execution, you’re confident this may be your best work yet.

Until the feedback starts rolling in.

There’s no sugar-coating it—things don’t always go as planned. But production or process issues are hardly a signal to throw in the towel. Instead, focus on honing your problem-solving skills to find a solution that keeps it from happening again.

The 8D method of problem solving emphasizes the importance of teamwork to not only solve your process woes but prevent new ones from occurring. In this guide, we’ll break down what 8D is, how to use this methodology, and the benefits it can give to you and your team. Plus, get an 8D template to make solving your issue easier.

See Asana in action

Drive clarity and impact at scale by connecting work and workflows to company-wide goals.

What is 8D?

The eight disciplines (8D) method is a problem-solving approach that identifies, corrects, and eliminates recurring problems. By determining the root causes of a problem, managers can use this method to establish a permanent corrective action and prevent recurring issues.

How do you use the 8D method?

The 8D method is a proven strategy for avoiding long-term damage from recurring problems. If you’re noticing issues in your workflow or processes, then it’s a good time to give this problem-solving method a try.

To complete an 8D analysis, follow “the eight disciplines” to construct a statistical analysis of the problem and determine the best solution.

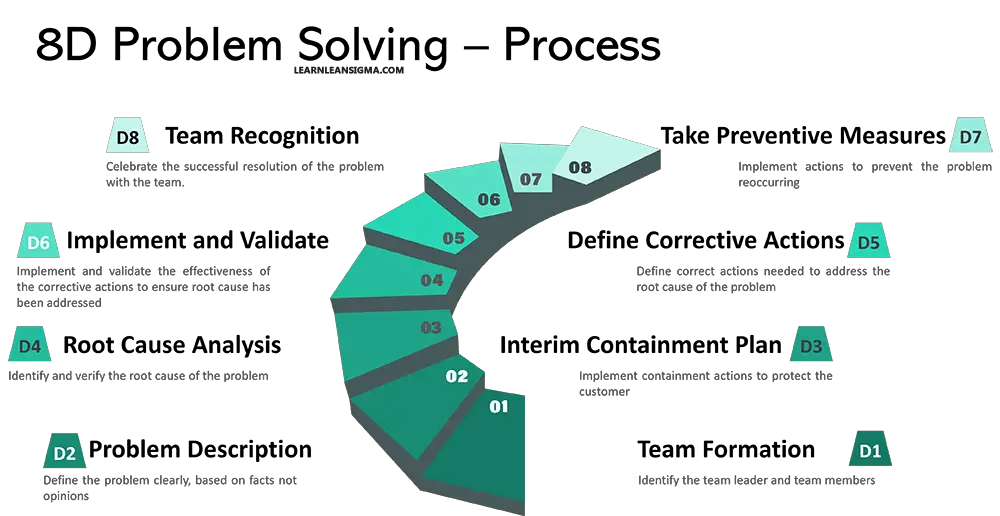

The eight disciplines of problem-solving

8D stands for the eight disciplines you will use to establish an 8D report. As you may notice, this outline starts with zero, which makes nine total disciplines. The “zero stage” was developed later as an initial planning stage.

To illustrate these steps, imagine your organization experienced a decline in team innovation and productivity this past year. Your stakeholders have noticed and want to see changes implemented within the next six months. Below, we’ll use the 8D process to uncover a morale-boosting solution.

![8d problem solving examples [inline illustration] D8 problem solving approach (infographic)](https://assets.asana.biz/transform/6ab7c188-3258-4d2e-afe6-9a4a084cc09f/inline-productivity-8d-template-1-2x?io=transform:fill,width:2560&format=webp)

D0: Prepare and plan

Before starting the problem-solving process, evaluate the problem you want to solve. Understanding the background of the problem will help you identify the root cause in later steps.

Collect information about how the problem has affected a process or product and what the most severe consequences may be. Planning can include:

Gathering data

Determining the prerequisites for solving the problem

Collecting feedback from others involved

![8d problem solving examples [inline illustration] D0 Planning (example)](https://assets.asana.biz/transform/abc3621d-e1ae-47ff-b731-0ee38cff99e9/inline-productivity-8d-template-2-2x?io=transform:fill,width:2560&format=webp)

If we look back at our example, you may want to figure out whether this decline in morale is organization-wide or only applies to a few departments. Consider interviewing a few employees from different departments and levels of management to gain some perspective. Next, determine what knowledge and skills you will need to solve this lapse in productivity.

D1: Form your team

Create a cross-functional team made up of people who have knowledge of the various products and workflows involved. These team members should have the skills needed to solve the problem and put corrective actions in place.

Steps in this discipline may include:

Appointing a team leader

Developing and implementing team guidelines

Determining team goals and priorities

Assigning individual roles

Arranging team-building activities

![8d problem solving examples [inline illustration] D1 Team members (example)](https://assets.asana.biz/transform/51986017-5150-4dd4-940c-252cd0eb8ba5/inline-productivity-8d-template-3-2x?io=transform:fill,width:2560&format=webp)

From our example, a solid team would consist of people with first-hand experience with the issues—like representatives from all departments and key people close to workshop-level work. You may also want to pull someone in from your HR department to help design and implement a solution. Most importantly, make sure the people you choose want to be involved and contribute to the solution.

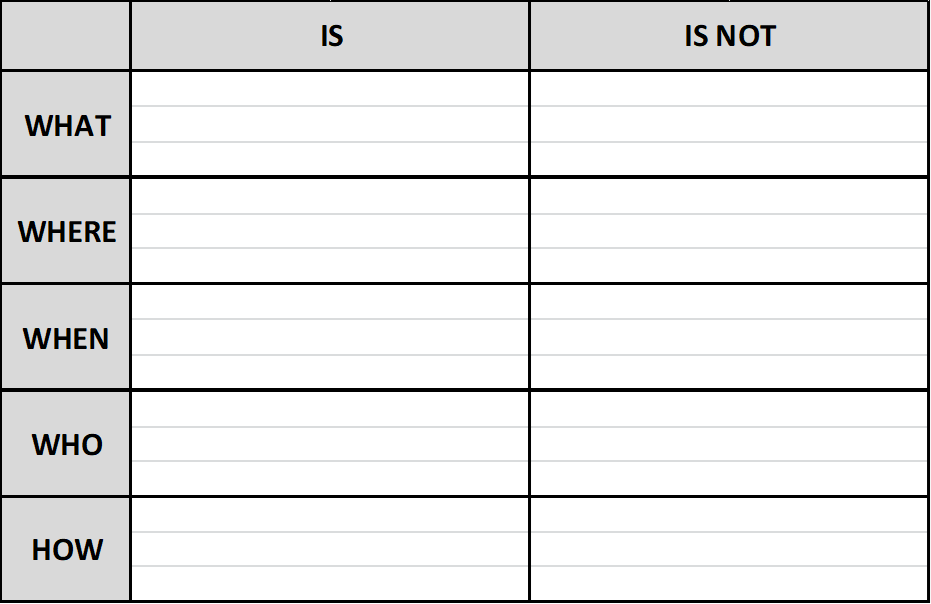

D2: Identify the problem

You may have a good understanding of your problem by now, but this phase aims to break it down into clear and quantifiable terms by identifying the five W’s a and two H’s (5W2H):

Who first reported the problem?

What is the problem about?

When did it occur and how often?

Where did it occur (relating to the sector, supplier, machine, or production line involved)?

Why is solving the problem important?

How was the problem first detected?

How many parts/units/customers are affected?

![8d problem solving examples [inline illustration] D2 Problem statement & description (example)](https://assets.asana.biz/transform/9825ecd6-2bd3-4559-a68c-b1ae8aca2e52/inline-productivity-8d-template-4-2x?io=transform:fill,width:2560&format=webp)

Use your team’s insights to answer these questions. From our example, your team may conclude that:

Employees feel overwhelmed with their current workload.

There is no real structure or opportunity to share new ideas.

Managers have had no training for meetings or innovation settings.

Disgruntled employees know they can achieve more—and want to achieve more—even if they seem disengaged.

Once you answer these questions, record an official problem statement to describe the issue. If possible, include photos, videos, and diagrams to ensure all parties have a clear understanding of the problem. It may also help to create a flowchart of the process that includes various steps related to the problem description.

D3: Develop an interim containment plan

Much like we can expect speedy first aid after an accident, your team should take immediate actions to ensure you contain the problem—especially if the problem is related to customer safety.

An interim containment plan will provide a temporary solution to isolate the problem from customers and clients while your team works to develop a permanent corrective action. This band-aid will help keep your customers informed and safe—and your reputation intact.

![8d problem solving examples [inline illustration] D3 Interim containment action (example)](https://assets.asana.biz/transform/d6279c36-ccc6-4de3-89d2-f221632a1059/inline-productivity-8d-template-5-2x?io=transform:fill,width:2560&format=webp)

Because your findings revealed workers were overworked and managers lacked training, your team suggests scheduling a few mandatory training sessions for leaders of each department covering time and stress management and combating burnout . You may also want to have a presentation outlining the topics of this training to get key managers and stakeholders interested and primed for positive upcoming changes.

D4: Verify root causes and escape points

Refer back to your findings and consult with your team about how the problem may have occurred. The root cause analysis involves mapping each potential root cause against the problem statement and its related test data. Make sure to test all potential causes—fuzzy brainstorming and sloppy analyses may cause you to overlook vital information.

![8d problem solving examples [inline illustration] D4 Root cause & escape points (example)](https://assets.asana.biz/transform/301717c6-0434-4c88-addf-d500dc23ae87/inline-productivity-8d-template-6-2x?io=transform:fill,width:2560&format=webp)

In our example, focus on the “why” portion of the 5W2H. You and your team identify six root causes:

Managers have never had any training

There is a lack of trust and psychological safety

Employees don’t understand the objectives and goals

Communication is poor

Time management is poor

Employees lack confidence

In addition to identifying the root causes, try to pinpoint where you first detected the problem in the process, and why it went unnoticed. This is called the escape point, and there may be more than one.

D5: Choose permanent corrective actions

Work with your team to determine the most likely solution to remove the root cause of the problem and address the issues with the escape points. Quantitatively confirm that the selected permanent corrective action(s) (PCA) will resolve the problem for the customer.

Steps to choosing a PCA may include:

Determining if you require further expertise

Ensuring the 5W2Hs are defined correctly

Carrying out a decision analysis and risk assessment

Considering alternative measures

Collecting evidence to prove the PCA will be effective

![8d problem solving examples [inline illustration] D5 Permanent corrective action (example)](https://assets.asana.biz/transform/53509966-18dd-4bb4-88a1-c7ca940fde3f/inline-productivity-8d-template-7-2x?io=transform:fill,width:2560&format=webp)

Your team decides to roll out the training used in the interim plan to all employees, with monthly company-wide workshops on improving well-being. You also plan to implement meetings, innovation sessions, and team-coaching training for managers. Lastly, you suggest adopting software to improve communication and collaboration.

D6: Implement your corrective actions

Once all parties have agreed on a solution, the next step is to create an action plan to remove the root causes and escape points. Once the solution is in effect, you can remove your interim containment actions.

After seeing success with the training in the interim phase, your stakeholders approve all of your team’s proposed PCAs. Your representative from HR also plans to implement periodic employee wellness checks to track employee morale .

![8d problem solving examples [inline illustration] D6 PCA implementation plan (example)](https://assets.asana.biz/transform/ca68af4a-afa7-4be4-93cb-8a8321eb5172/inline-productivity-8d-template-8-2x?io=transform:fill,width:2560&format=webp)

To ensure your corrective action was a success, monitor the results, customer, or employee feedback over a long period of time and take note of any negative effects. Setting up “controls” like employee wellness checks will help you validate whether your solution is working or more needs to be done.

D7: Take preventive measures

One of the main benefits of using the 8D method is the improved ability to identify necessary systematic changes to prevent future issues from occurring. Look for ways to improve your management systems, operating methods, and procedures to not only eliminate your current problem, but stop similar problems from developing later on.

![8d problem solving examples [inline illustration] D7 Preventive measure (example)](https://assets.asana.biz/transform/cdd7b133-fb80-4db7-8935-1285a6b62b69/inline-productivity-8d-template-9-2x?io=transform:fill,width:2560&format=webp)

Based on our example, the training your team suggested is now adopted in the new manager onboarding curriculum. Every manager now has a “meeting system” that all meetings must be guided by, and workloads and projects are managed as a team within your new collaboration software . Innovation is improving, and morale is at an all-time high!

D8: Celebrate with your team

The 8D method of problem-solving is impossible to accomplish without dedicated team members and first-class collaboration. Once notes, lessons, research, and test data are documented and saved, congratulate your teammates on a job well done! Make an effort to recognize each individual for their contribution to uncovering a successful solution.

![8d problem solving examples [inline illustration] 8D Team congratulations & reward (example)](https://assets.asana.biz/transform/d2055965-bf3d-4bf4-a1ea-a0a7c4bf8a32/inline-productivity-8d-template-10-2x?io=transform:fill,width:2560&format=webp)

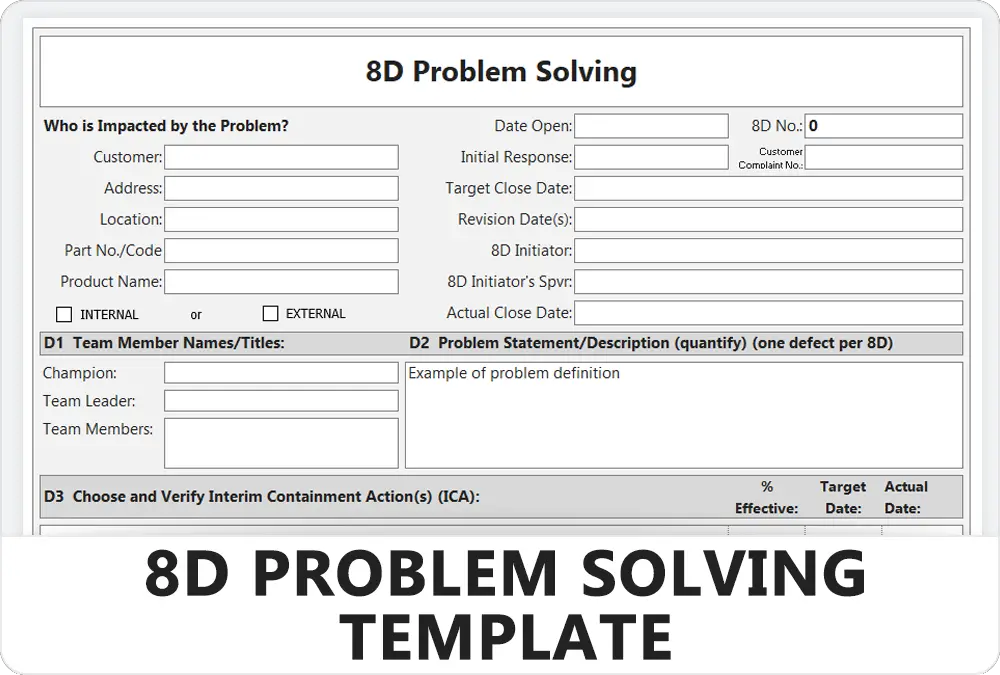

8D report template and example

Check out our 8D report template below to help you record your findings as you navigate through the eight disciplines of problem solving. This is a formal report that can be used as a means of communication within companies, which makes for transparent problem-solving that you can apply to the entire production or process chain.

Benefits of using the 8D method

The 8D method is one of the most popular problem-solving strategies for good reason. Its strength lies in teamwork and fact-based analyses to create a culture of continuous improvement —making it one of the most effective tools for quality managers. The benefits of using the 8D method include:

Improved team-oriented problem-solving skills rather than relying on an individual to provide a solution

Increased familiarity with a problem-solving structure

A better understanding of how to use basic statistical tools for problem-solving

Open and honest communication in problem-solving discussions

Prevent future problems from occurring by identifying system weaknesses and solutions

Improved effectiveness and efficiency at problem-solving

Better collaboration = better problem solving

No matter how good a manager you are, production and process issues are inevitable. It’s how you solve them that separates the good from the great. The 8D method of problem solving allows you to not only solve the problem at hand but improve team collaboration, improve processes, and prevent future issues from arising.

Try Asana’s project management tool to break communication barriers and keep your team on track.

Related resources

What is resource management? A guide to getting started

What is a product backlog? (And how to create one)

How to use benchmarking to set your standards for success

How to scale retail management operations with Asana

Guide: 8D Problem Solving

Author: Daniel Croft

Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

8D Problem Solving is a systematic and structured approach used to solve business related problems. It names has been given by the fact there are 8 steps or 8 disciplines that are followed to identify, correct and eliminate recurring problems.

8D Problem Solving is regarded as robust methodology that has proven its worth across multiple industries and manufacturing in particular. The methodology was Initially developed within the automotive industry, it has since been widely adopted in manufacturing, logistics and health care to name a few. The 8D approach goes beyond helping team just identify the root cause of problem but also provides a structured approach for implementing and verifying corrective actions.

What is 8D Problem Solving?

The 8D Problem-Solving methodology was developed in the late 1980s by Ford Motor Company. The term “8D” stands for “Eight Disciplines,” which represent the eight critical steps in problem-solving.

Initially it was only intended to resolve issues within the automotive manufacturing process. However, over the year since then the methodology has gained universal acceptance and is now applied across various sectors. The 8D approach was heavily influenced by quality management systems like Total Quality Management (TQM) and methodologies like Six Sigma and forms a key part of quality roles and Six sigma qualifications.

8D is also encourages collaborative team based approach to addressing issues in the workplace This methodology was purposefully designed to be a cross-functional effort, ensuring to bring together expertise from different departments or disciplines to comprehensively address an issue by looking at it from all point of view. Here are the key components:

Preparation : Before diving into problem-solving, the team gathers all necessary resources and tools.

Team Establishment : A cross-functional team is assembled, each member having a specific role and responsibility.

Problem Description : The issue at hand is clearly defined to ensure everyone has a shared understanding.

Interim Actions : Short-term solutions are implemented to contain the problem and prevent further damage.

Root Cause Analysis : Various tools and methods are used to identify the real cause of the problem.

Permanent Corrective Actions : Long-term solutions are selected and verified to eliminate the root cause.

Implementation : The long-term solutions are implemented across the board, including necessary changes to policies and procedures.

Prevent Recurrence : Measures are taken to ensure that the problem does not occur again.

Team Recognition : The team is congratulated and acknowledged for their efforts.

Want exclusive templates, tools and guides?

Join our email list below and for the next 28 days, we will send you exclusive tools, templates and guides unavailable on the website. We developed a short and simple 28-day program designed to develop your ability to implement Lean and Six Sigma methods daily.

How does 8D Compare to over Problem-Solving Methods?

Between quality management systems and lean six sigma there are several problem-solving methodologies such as PDCA (Plan-Do-Check-Act), DMAIC (Define-Measure-Analyze-Improve-Control), and A3 . However the combination of the 8D steps results in a comprehensive frame work that is:

Team-Oriented : Unlike some methodologies that can be carried out by individuals, 8D strongly emphasizes team collaboration as a core principle as seen in steps D1 and D8.

Structured Framework : 8D provides a very detailed, step-by-step guide for solving complex problems, by breaking it down in to logical steps making it easier to manage and track progress.

Broad Applicability : While some methodologies like DMAIC are closely tied to Six Sigma, 8D can be applied in various contexts without being tied to a particular quality management system.

Focus on Prevention : 8D not only aims to solve the problem but also focuses on implementing changes to prevent its recurrence, making it a complete approach to problem solving.

The 8 Disciplines Explained

D0: prepare for the process.

Before you start 8D you should prepare for the 8D process. This phase sets the foundation for the entire methodology, ensuring that the team is able to tackle the problem effectively. Therefore, effective preparation helps in avoiding unnecessary delays and ensures that you’re not solving the wrong problem.

Within the initial preparation step you should also the time to think about what knowledge, expertise and experience you need within the team. Cross-functional teams are important, as they bring alternative perspectives and skills to the table rather than everyone looking at the problem from one point of view. Make sure you consider expertise, availability, and interest when selecting team members.

D1: Establish the Team

In D1 you should establish the team by clearly defining the roles and responsibilities for each team member. This includes assigning a team leader, subject matter experts, and roles for data collection , analysis, and communication this helps to provide the team members clarity on how they will be involved and contribute to the success of the problems solving activity.

Team Composition

Once roles are defined, where possible ensure that the team is balanced in terms of skills and expertise. A well-rounded team will be more effective in tackling various aspects of the problem.

Communication

Establish clear methods communication, both within the team and with external stakeholders. Such as deciding on regular meeting schedules that everyone can attend, reporting formats, and tools for collaboration.

D2: Describe the Problem

In D2 it is time to create a well formed problem statement. This step is key as it provides a foundation for understanding the problem which will lead to generally more successful problem-solving. It ensures that everyone clearly understands what needs to be addressed, setting the scope for the entire process. Ensure that the problem is clearly understood by everyone in the team at this stage to prevent confusion later on in the process.

5W1H Method of creating a Problem Definition

Use data gathering techniques such as observations, interviews, and document reviews can help to precisely identify the problem. A useful tool to use at this stage could be the 5W1H Problem definition method.

You can find out more about this method with our 5W1H guide .

Problem Definition – is / is not template

When creating your problem definition ensure to be specific, measurable, and unambiguous when stating the problem. You should avoid generalities and ensure that the problem statement is understandable to someone unfamiliar with the issue. If you are new to this process it may be helpful to give the statement to someone unfamiliar to the process and see if they understand it or if they have questions. You can then clarify any questions by adjusting the problem description to improve the claity.

D3: Implement and Verify Interim Actions

In D3 while the team is investigating the root cause, interim actions are must be implement to contain the problem and minimize its impact. This is particularly important in critical situations affecting safety, compliance, or customer satisfaction.

In this step you should identify, plan, and execute short-term fixes that can quickly contain the problem. This could include quarantining the product to ensure it is not sent out to the customer or even pausing production lines that continue to product defects. Ensure these actions are documented for future reference.

Use metrics and KPIs to gauge the effectiveness of the interim actions. Make adjustments as necessary.

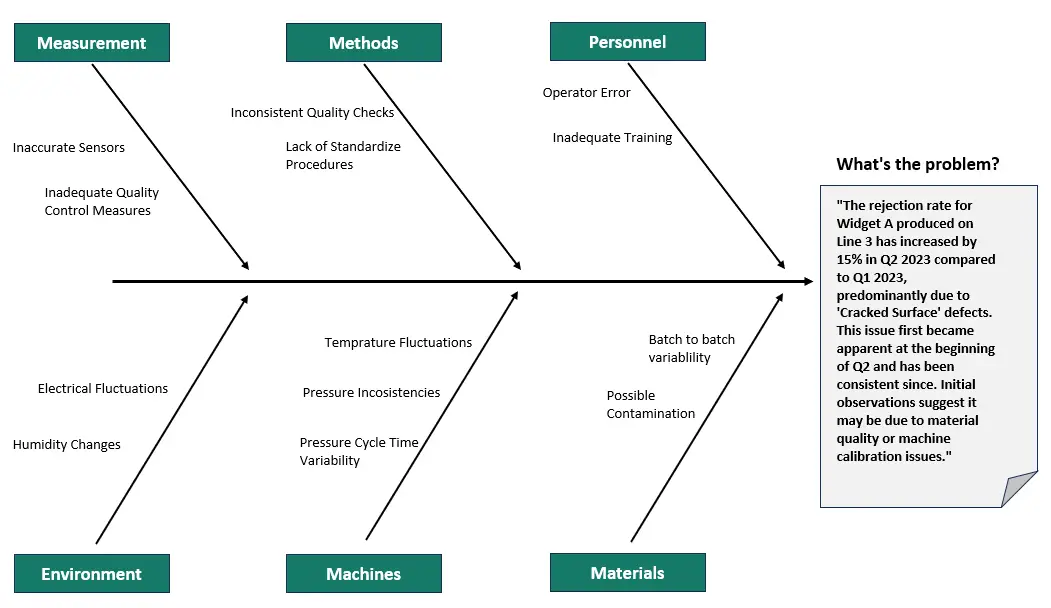

D4: Root Cause Analysis

D4 is where you start to understand what is causing the issue by identifying the underlying reason for the problem. The objective is to find the root cause, not just the symptoms.

At this stage there are a range of quality and lean six sigma tools that can be used to conduct root cause analysis , which can include the Fishbone Diagram for structured brainstorming and the 5 Whys technique for causal chain analysis.

We have a range of guides on all of these techniques for you to use.

Once identified, it is important validate the root cause through experimentation or additional data analysis to ensure it’s the actual cause and not a symptom, this can often be an overlook critical step in the root cause process.

D5: Choose and Verify Permanent Corrective Actions

In D5 you need to choose what actions to be taken to prevent the problem reoccurring and any solutions implemented should be verified that the actions correct the problem this can involve trial runs, further data collection and inspections of product or services being produced.

You should also consider factors like cost, impact, and feasibility when choosing a permanent corrective action and should also conduct a risk assessment to evaluate potential negative outcomes of the actions taken

An implementation or action plan is often useful to document at this stage to detail the steps for implementation, assign responsibilities, and set timelines.

D6: Implement Permanent Corrective Actions

Once verified, implement the corrective actions across all relevant departments or processes. This can involved documenting the new process and training out to all stakeholders involved to ensure the new process is followed and that the stakeholders understand the reason for the change.

At this point you should continue to regularly monitor the situation to ensure the corrective actions are sustained and effective, this could be for a period of 30, 60 or 90 days after the problem was resolved to ensure the new process has become a sustained and issues do not reoccur.

D7: Prevent Recurrence

In D7 to prevent recurrent you should review and update organizational policies or standard operating procedures (SOPs) to prevent a recurrence of the problem and document the new standard process

It is important to conduct regular reviews to continuously monitor the process and ensure procedures are being followed but also to identify further opportunities for process improvement.

D8: Congratulate the Team

The final step D8, after the hard work and successful problem resolution, it is important to acknowledging and congratulating the team is vital for morale and future engagement. With the recognition of a successful 8D Problem-solving activity complete you are more likely to encourage future participation as the method gets a reputation as being useful and successful at solving problems.

Whether it’s a team lunch, certificates of achievement, or simply a public acknowledgment, celebrate the success in a way that resonates with your team.

Finally it is always important to conduct a lessons-learned session and document the insights gained during the process for future reference. This can be used as a future point of reference for problem solving activities.

Mastering the art of problem-solving is crucial in today’s complex and fast-paced environment. The 8D Problem-Solving methodology offers a structured, team-based approach to tackling challenges that can arise in any sector, be it manufacturing, public services, or logistics. This guide has walked you through each of the eight disciplines, offering best practices and highlighting common pitfalls to avoid. We’ve also enriched your understanding through real-world case studies that demonstrate the methodology’s versatility and effectiveness. Remember, the strength of 8D lies not just in identifying and resolving problems, but also in preventing their recurrence through systemic improvements. By adhering to the principles and steps outlined in this guide, you’re well on your way to becoming an adept problem solver, capable of driving continuous improvement in your organization.

- Zarghami, A. and Benbow, D.W., 2017. Introduction to 8D problem solving . Quality Press.

- Camarillo, A., Ríos, J. and Althoff, K.D., 2017. CBR and PLM applied to diagnosis and technical support during problem solving in the Continuous Improvement Process of manufacturing plants . Procedia Manufacturing , 13 , pp.987-994.

Q: What is 8D problem solving?

A: 8D problem solving is a systematic approach used to address and resolve complex problems. It is widely utilized in various industries to identify the root causes of issues, develop effective solutions, and prevent their recurrence.

Q: Why is it called "8D" problem solving?

A: The name “8D” refers to the eight disciplines or steps involved in the problem-solving process. Each discipline represents a specific stage in the methodology, allowing for a structured and comprehensive approach to problem resolution.

Q: What are the eight disciplines (8D) in problem solving?

A: The eight disciplines in problem solving, often abbreviated as 8D, are as follows:

- D1: Form a team

- D2: Define the problem

- D3: Implement containment actions

- D4: Determine the root cause

- D5: Develop and implement corrective actions

- D6: Validate the effectiveness of corrective actions

- D7: Prevent recurrence

- D8: Congratulate the team

Q: What is the purpose of forming a team in the 8D problem-solving process?

A: Forming a team at the beginning of the 8D problem-solving process helps ensure that the right individuals with the necessary expertise are involved in addressing the problem. The team collaboratively works towards understanding the issue, analyzing data, and developing effective solutions.

Q: How is the root cause determined in the 8D problem-solving process?

A: Determining the root cause (D4) involves conducting a thorough analysis of the problem. Various tools and techniques, such as cause-and-effect diagrams, 5 Whys, and data analysis, are employed to identify the underlying factors contributing to the problem.

Q: Can the 8D problem-solving methodology be applied to any type of problem?

A: Yes, the 8D problem-solving methodology is a versatile approach that can be applied to various types of problems across different industries. It provides a structured framework for problem resolution and can be tailored to suit the specific needs and requirements of different situations.

Daniel Croft

Hi im Daniel continuous improvement manager with a Black Belt in Lean Six Sigma and over 10 years of real-world experience across a range sectors, I have a passion for optimizing processes and creating a culture of efficiency. I wanted to create Learn Lean Sigma to be a platform dedicated to Lean Six Sigma and process improvement insights and provide all the guides, tools, techniques and templates I looked for in one place as someone new to the world of Lean Six Sigma and Continuous improvement.

Download Template

Free Lean Six Sigma Templates

Improve your Lean Six Sigma projects with our free templates. They're designed to make implementation and management easier, helping you achieve better results.

Was this helpful?